Navigating Regulatory Challenges in Pharma: The Role of Innovative Packaging Solutions

In today's dynamic pharmaceutical industry, smart packaging systems have become indispensable. These systems play a pivotal role in ensuring regulatory compliance and meeting stringent packaging standards while addressing the complexities of packaging and testing requirements. Pharma companies are actively embracing innovative packaging solutions as a strategic approach to enhance the safety, efficacy, and overall quality of their products.

The adoption of smart packaging systems signifies a proactive stance by pharmaceutical companies towards fulfilling regulatory compliance mandates. These systems integrate advanced technologies such as RFID tracking, temperature monitoring, and real-time data collection, ensuring that products are handled and stored within specified parameters. By leveraging these technologies, companies can streamline their packaging and testing processes, ensuring that products are packaged appropriately and undergo rigorous quality assessments.

Moreover, the use of smart packaging systems extends beyond mere compliance; it is a strategic investment in product integrity and patient safety. These systems enable real-time monitoring of factors like temperature, humidity, and storage conditions, ensuring that pharmaceutical products remain stable and effective throughout their shelf life. This level of monitoring and control not only meets packaging standards but also enhances overall product quality and reliability. When considering secondary packaging materials, pharmaceutical companies are now seeking innovative solutions that not only meet regulatory requirements but also align with sustainability goals. Eco-friendly materials that maintain product integrity while reducing environmental impact are gaining prominence in the industry. This shift reflects a broader commitment to responsible packaging practices while ensuring regulatory compliance and meeting packaging standards.

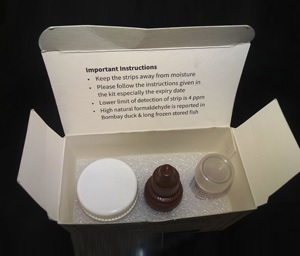

Within the domain of pharmaceutical packaging, medical test packages occupy a critical niche. These packages require specialized considerations due to the nature of their contents, which often include sensitive diagnostic materials. Smart packaging systems tailored for medical test packages ensure specimen integrity, tamper resistance, and clear labeling, all essential aspects for meeting regulatory compliance and maintaining patient safety.

In essence, the strategic adoption of smart packaging systems and innovative packaging solutions is not merely a response to regulatory requirements; it is a proactive approach that enhances product quality, ensures regulatory compliance, and fosters trust among consumers and regulatory agencies alike. By prioritizing these elements, pharmaceutical companies can navigate the intricate landscape of regulatory frameworks while advancing the safety, efficacy, and reliability of their products.

The Importance of Regulatory Compliance

Regulatory compliance stands as a cornerstone in the pharmaceutical industry, underpinning the safety, efficacy, and quality of pharmaceutical products. The sector operates under stringent regulatory requirements imposed by authoritative bodies such as the FDA and EMA, which set forth comprehensive packaging standards and labeling guidelines. In this intricate regulatory landscape, smart packaging systems emerge as indispensable tools, playing a pivotal role in ensuring regulatory compliance.

Pharmaceutical companies must adhere to a myriad of regulations to bring their products to market. These regulations encompass every aspect of the product lifecycle, from manufacturing and packaging to distribution and labeling. Regulatory compliance is non-negotiable, as it not only safeguards public health but also maintains industry integrity and trust. Smart packaging systems are designed to align seamlessly with these regulations, offering features that facilitate adherence to packaging standards and regulatory mandates.

The FDA and EMA, among other regulatory bodies, mandate precise requirements for packaging and testing to ensure product safety and efficacy. Smart packaging systems integrate technologies such as temperature monitoring, tamper-evident features, and real-time tracking, enabling pharmaceutical companies to meet these requirements with precision. These systems streamline the packaging and testing processes, ensuring that products are packaged securely, undergo rigorous quality checks, and maintain their integrity throughout the supply chain.

Furthermore, secondary packaging materials are carefully selected to comply with regulatory guidelines while addressing environmental concerns. Eco-friendly materials that meet packaging standards without compromising product safety are increasingly favored, reflecting a commitment to sustainable practices alongside regulatory compliance. In the realm of medical test packages, which encompass sensitive diagnostic materials, smart packaging systems are tailored to meet stringent regulatory demands. These systems ensure specimen integrity, prevent contamination, and provide clear labeling to meet regulatory compliance requirements and uphold patient safety.

In summary, smart packaging systems are not just technological advancements; they are strategic solutions that enable pharmaceutical companies to navigate the intricate landscape of regulatory compliance effectively. By embracing these systems, companies can uphold the highest standards of safety, efficacy, and quality while meeting the expectations of regulatory agencies and consumers alike.

Smart Packaging Systems in Pharma

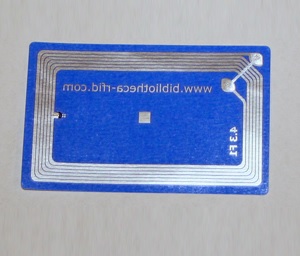

Smart packaging systems have revolutionized the pharmaceutical industry by seamlessly integrating cutting-edge technologies to ensure product safety, regulatory compliance, and enhanced operational efficiency. These systems, encompassing features like RFID tags, temperature sensors, and tamper-evident seals, represent a paradigm shift in smart packaging system design, offering comprehensive solutions that address diverse industry challenges.

The incorporation of RFID tags within smart packaging systems enables real-time tracking and monitoring of pharmaceutical products throughout the supply chain. This level of visibility not only enhances regulatory compliance by ensuring adherence to stringent packaging standards but also facilitates swift identification and resolution of any potential issues during transit or storage. The ability to track products at every stage of their journey contributes significantly to improved traceability and accountability, factors critical in maintaining product integrity and consumer trust.

Temperature sensors embedded within smart packaging systems play a pivotal role in safeguarding product efficacy and quality. These sensors monitor environmental conditions, such as temperature fluctuations, ensuring that pharmaceutical products are stored and transported within specified parameters. By maintaining optimal storage conditions, smart packaging systems mitigate the risk of product degradation, thereby upholding regulatory compliance standards related to product stability and efficacy.

Tamper-evident seals are another key feature of smart packaging systems that bolster security and authenticity. These seals provide visible evidence of tampering or unauthorized access, alerting stakeholders to potential risks and ensuring product authenticity throughout the supply chain. Such measures are instrumental in meeting packaging and testing requirements, particularly in safeguarding against counterfeit products and ensuring that only genuine, quality-assured pharmaceuticals reach consumers.

Moreover, the holistic approach of smart packaging systems extends to considerations of secondary packaging materials. By leveraging advanced materials that meet regulatory guidelines while addressing environmental concerns, these systems contribute to sustainable practices without compromising on product safety or quality. This alignment with packaging standards underscores the versatility and adaptability of smart packaging systems in meeting evolving industry needs. In the realm of medical test packages, smart packaging systems tailored for these specialized products ensure uncompromised specimen integrity, secure handling, and clear labeling, all essential aspects in achieving regulatory compliance and maintaining patient safety.

In essence, smart packaging systems represent a convergence of innovation and regulatory adherence in the pharmaceutical sector, offering a comprehensive solution that enhances traceability, security, and product integrity while meeting stringent packaging standards and regulatory compliance requirements.

Addressing Packaging Challenges

Addressing the challenges posed by pharmaceutical packaging is imperative for ensuring product safety, regulatory compliance, and environmental sustainability. A key aspect of this challenge lies in the selection of secondary packaging materials, which play a crucial role in safeguarding pharmaceutical products during storage, transport, and distribution.

In recent years, innovations in materials science have catalyzed the development of eco-friendly yet robust secondary packaging materials. These materials strike a delicate balance between meeting stringent regulatory requirements and addressing environmental concerns, offering pharmaceutical companies viable solutions that align with packaging standards while prioritizing safety and sustainability.

The evolution of smart packaging systems has played a significant role in this paradigm shift. These systems not only integrate advanced technologies for real-time monitoring and security but also leverage innovative materials that meet regulatory guidelines. By embracing eco-friendly secondary packaging materials, pharmaceutical companies demonstrate their commitment to responsible packaging practices without compromising on product safety or efficacy.

Furthermore, the development of robust secondary packaging materials enhances product protection during packaging and testing processes, mitigating risks associated with contamination, breakage, or tampering. These materials undergo rigorous testing to ensure they meet industry standards and regulatory mandates, thereby contributing to overall product integrity and quality assurance.

The adoption of eco-friendly secondary packaging materials also aligns with broader sustainability initiatives within the pharmaceutical industry. By reducing the environmental footprint of packaging materials, companies contribute to mitigating waste generation and promoting circular economy principles. This holistic approach not only fulfills regulatory compliance requirements but also reflects a commitment to ethical and environmentally conscious practices.

In the context of medical test packages, the selection of appropriate secondary packaging materials is paramount. These packages, often containing sensitive diagnostic materials, require specialized considerations to ensure specimen integrity, tamper resistance, and clear labeling. Smart packaging systems tailored for medical test packages incorporate eco-friendly materials that meet packaging standards while addressing unique regulatory demands, thus ensuring product authenticity and patient safety.

In conclusion, the ongoing advancements in secondary packaging materials underscore the industry's proactive approach towards addressing packaging challenges. By embracing eco-friendly solutions that meet regulatory compliance and packaging standards, pharmaceutical companies pave the way for sustainable packaging practices that safeguard product integrity, promote environmental stewardship, and enhance consumer trust.

The Role of Medical Test Packages

Medical test packages represent a specialized segment within pharmaceutical packaging, necessitating tailored solutions to address the unique challenges posed by their sensitive contents. These packages undergo stringent scrutiny to ensure regulatory compliance and adherence to packaging standards while prioritizing specimen integrity, temperature control, and clear labeling.

Innovative smart packaging systems designed specifically for medical test packages play a pivotal role in maintaining product integrity and meeting regulatory demands. These systems integrate advanced technologies such as temperature-controlled compartments, tamper-evident features, and real-time monitoring capabilities, ensuring that perishable samples are safeguarded throughout their journey.

Specimen integrity is a paramount concern in medical test packages, as any compromise could lead to inaccurate results or compromised patient care. Smart packaging systems incorporate robust materials and design elements that protect specimens from contamination, temperature fluctuations, and physical damage, thereby upholding the highest standards of specimen integrity.

Temperature control is another critical aspect addressed by smart packaging systems for medical test packages. Perishable samples require precise temperature management to maintain their stability and validity. These systems employ temperature sensors, insulated compartments, and monitoring mechanisms to ensure that samples remain within specified temperature ranges, thus meeting both regulatory compliance requirements and quality standards.

Clear labeling is essential for medical test packages to facilitate accurate identification, tracking, and handling. Smart packaging systems incorporate intuitive labeling solutions that include essential information such as specimen type, storage conditions, handling instructions, and expiration dates. This comprehensive labeling not only meets packaging standards but also enhances traceability and reduces the risk of errors in sample handling.

In summary, innovative smart packaging systems tailored for medical test packages exemplify the industry's commitment to regulatory compliance, packaging standards, and patient safety. By addressing the unique considerations of specimen integrity, temperature control, and clear labeling, these systems ensure that medical test packages meet the stringent demands of regulatory agencies while maintaining the highest levels of quality and reliability in diagnostic testing.

Five Steps to Risk Assessment

Risk assessment is a systematic process that plays a fundamental role in ensuring regulatory compliance, maintaining packaging standards, and enhancing product safety in pharmaceutical packaging and testing. The following five steps outline a comprehensive approach to risk assessment, incorporating considerations such as smart packaging systems, secondary packaging materials, and medical test packages:

1. Identify hazards: The first step in risk assessment involves identifying potential hazards associated with the packaging process. This includes assessing material compatibility issues, environmental factors such as temperature fluctuations or humidity levels, and regulatory requirements related to packaging and testing. By thoroughly examining these factors, companies can pinpoint areas of potential risk that may impact product quality or regulatory compliance.

2. Assess the risks: Once hazards are identified, the next step is to assess the risks associated with each hazard. This involves evaluating the potential impact on product quality, patient safety, and regulatory compliance. Factors such as shelf life, transport conditions, and storage requirements are considered in this assessment to determine the severity of risks and prioritize risk management strategies.

3. Control the risks: Risk control measures are implemented to mitigate identified risks and ensure product safety and regulatory compliance. This may include using appropriate secondary packaging materials to protect products during transit, incorporating tamper-evident features to prevent unauthorized access, and integrating tracking technologies within smart packaging systems for real-time monitoring. These control measures aim to reduce the likelihood of risks and their potential consequences.

4. Record your findings: It is crucial to maintain detailed records of the risk assessment process, including hazard identification, risk evaluation, and control measures implemented. This documentation serves as evidence of regulatory compliance and provides a basis for continuous improvement. Regulatory agencies may require companies to demonstrate their risk assessment processes and the measures taken to mitigate risks effectively.

5. Review the controls: Continuous review and update of risk control measures are essential to adapt to changing regulatory requirements, technological advancements, and feedback from quality assurance processes. Regular reviews ensure that risk management strategies remain effective in mitigating risks and maintaining product safety. Continuous improvement is key to ensuring ongoing regulatory compliance and enhancing product quality and safety in packaging and testing processes.

Incorporating these five steps into the risk assessment process enables pharmaceutical companies to proactively manage risks, uphold packaging standards, and meet regulatory compliance requirements while ensuring the safety and integrity of medical test packages and other pharmaceutical products.

Conclusion

In conclusion, the integration of smart packaging systems within innovative packaging solutions has become instrumental in assisting pharmaceutical companies to effectively navigate complex regulatory challenges. These systems, powered by advanced technologies and aligned with stringent packaging standards, play a crucial role in enhancing product safety, ensuring regulatory compliance, and ultimately, improving patient outcomes.

By embracing packaging standards set forth by regulatory agencies such as the FDA and EMA, pharmaceutical companies demonstrate their commitment to upholding the highest levels of quality and safety in their products. This includes meticulous attention to detail in packaging and testing processes, selection of appropriate secondary packaging materials to protect products during storage and transport, and compliance with labeling requirements for medical test packages and other pharmaceutical products.

The incorporation of smart packaging systems adds a layer of sophistication and efficiency to these efforts. These systems integrate technologies such as RFID tags, temperature sensors, and tamper-evident features, enabling real-time monitoring, precise control, and enhanced security throughout the supply chain. Such capabilities not only contribute to meeting regulatory compliance requirements but also streamline operations and reduce risks associated with product handling and distribution.

Furthermore, a structured approach to risk assessment, as outlined in the previous sections, ensures that potential hazards are identified, evaluated, and mitigated effectively. By following a systematic risk assessment approach and maintaining detailed records of risk management processes, pharmaceutical companies can demonstrate regulatory compliance and continuous improvement in product safety and quality.

In essence, the synergy between smart packaging systems, innovative packaging solutions, adherence to packaging standards, and structured risk assessment methodologies forms the cornerstone of success for pharmaceutical companies in navigating regulatory challenges. This integrated approach not only enhances operational efficiency but also fosters trust among stakeholders, ensures patient safety, and contributes to the overall advancement of healthcare outcomes.