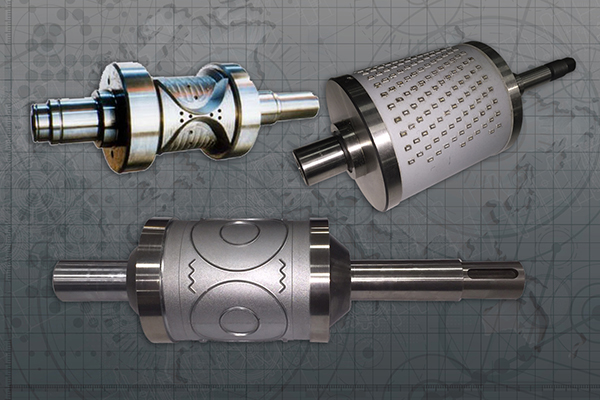

Crush Cut Dies

We invented the solid hardened rotary die in the late 1960s by creating a wedge-type cutting edge on a solid cylinder through the use of EDM (electric discharge machining). Our proprietary process allows us to precisely manufacture dies, thereby achieving high-quality cuts at high speeds for countless materials and products.

We make our crush cut rotary dies from solid tool steel, assuring an exceptional level of hardness and longevity. We manufacture these dies to exacting tolerances in order to ensure a precise cut, smooth die rotation, and consistently accurate results.

Reasons to Use Crush Cut Dies:

Capable of extremely high-speed operation

Machine sharpening

Fully-hardened, solid steel construction for strength and longevity

Dies can be partially or fully segmented

Capable of quick-changing

Precise cutting shape tolerances

Scrap stripping

Sharpening Crush Cut Dies

Each crush cut die produced at Bernal is durable enough to withstand multiple sharpenings throughout its die life. Each time we sharpen a Bernal crush cut die we bring it back to the same flawless quality it had when it left our facility, keeping it as precise and consistent as the day you installed it.

Partially or Fully Segmented Rotary Dies

Our crush cut dies can feature specially designed segments and removable rings to accommodate a wide variety of applications and enable selective repair of high wear areas. In addition to cutting, these partial or fully segmented dies are also perfectly suited to embossing and laminating. The removable segments turn a generic carton die into a fully customizable solution for several end-users simply by changing customer specific segments in the die, spreading the cost justification of a single die set over multiple customers and applications.

High-precision machining techniques are essential to producing dies with exceptionally long life-spans. Our Advanced Machining Lab with a climate controlled environment ensures that your die is manufactured to the highest standards, using CAD/CAM, CNC and CMM inspection.