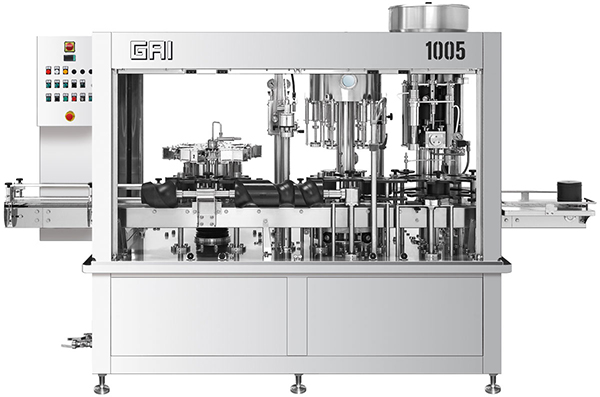

RINSING - DEAERATION - DRAFT – CLOGGING 1005

RINSING - DEAERATION - DRAFT – CLOGGING 1005

CADENCE:• Up to 1200 bottles / hourTECHNICAL DESCRIPTION:• Rinser 6 positions• Deaerator 1 post• Haul 6 positions• Capping 1 post• Flat products

RINSER

Stainless steel rinser for bottles with a maximum diameter of 115 mm. The jaws take the bottle by the neck and it is turned over mechanically by means of a rack. The injector enters the bottle over a length of 70 mm. The injection is done only in the presence of the bottle by a system avoiding any glass / metal contact. The draining liquid is collected by a closed circuit without wetting the machine. The jaws return to their normal position and, when opening, allow the exit star to put the bottle on the conveyor again. Electric height adjustment.

BOTTLE DEAERATION STATION

A high efficiency vacuum pump removes approximately 90% of the air from the bottle. After which, the bottle is filled with neutral gas. It is generally advisable to use nitrogen or alternatively CO2 or a nitrogen / CO2 mixture. The air aspiration and the injection of neutral gas are only done if the bottle is present. Thanks to our filling spouts (patented), the same atmosphere is created in the tank of the filler as in the bottle. Electric height adjustment as standard

GAS INJECTOR

The injection of neutral gas before corking significantly reduces the quantity of oxygen between the product and the stopper (the injector is fitted with a dummy bottle for sterilization).

CORK CORKER

The cork corker slowly closes the cork with four hardened, ground and polished stainless steel jaws. The vacuum is thus created with a high efficiency vacuum pump in the neck of the bottle so that the rapid introduction of the stopper does not create pressure, thus avoiding the risk of sagging. The disassembly of the head and the centering cone is very simple. We have taken extreme care in the construction of the corking head: the roughness of the surfaces in contact with the cork is less than 0.09 microns. The tightening of the cork is slow (105 °), the insertion of the cork is rapid (53 °).