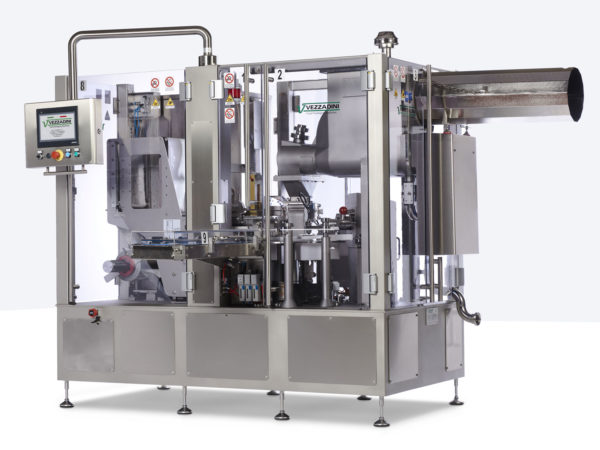

Vezzadini KRX Industrial butter and margarine packer

Description

The KRX model has been developed for the industrial packaging of butter and margarine. It is a robust machine, designed for intensive use. The basic operating principle is mechanical, with the addition of some servomotors to achieve maximum versatility of use. The machine body frame and most of components of the KRX are stainless steel made.

It can be used to package margarine, traditional butter, reduced fat content butter, butter with salt in grains, butter with herbs and blends of butter and vegetable oil.

The KRX can be supplied with four different types of product feeding units

- stainless steel direct feeding unit for margarine and blends of butter and vegetable oil with piston compensator and return pipe connection. It is predisposed for CIP cleaning

- stainless steel hopper with motorised feeding screws predisposed for C.I.P. cleaning. The hopper can be automatically fed or manually with small butter blocks

- stainless steel direct feeding unit for butter with large capacity cylinder (24 kg) predisposed for C.I.P. cleaning

The packs are wrapped bottom fold style and they can be closed in three ways:

- self adhesive label

- hot melt glue

- simple folding

The KRX can wrap using several types of wrapping material such as parchment paper, coupled aluminium and some plastic based materials.

The weight of packs goes from 50g up to 250g.

The size change-over time is always less than 30 minutes.

The KRX can dose and wrap up to 85 packs per minute.

The machine is fitted with touch screen operator panel to set the working parameters. Lubrication is centralised with automatic programmable pump.

The machine is equipped with a LAN router for on-line monitoring and assistance and it is predisposed for the connection with a checkweigher with feedback to the volumetric doser.

The wrapping material feeding section has been designed to integrate a thermal transfer overprinter.