Articles

Instant Fast Food in Retort Pouches

A retort pouch is a plastic and metal foil laminate pouch that is used as an alternative to traditional industrial canning methods. A pouch is a bag with 3 or 4 wide seals, which can store liquid within. Some varieties have a bottom gusset and are known as Stand-Up Pouches.

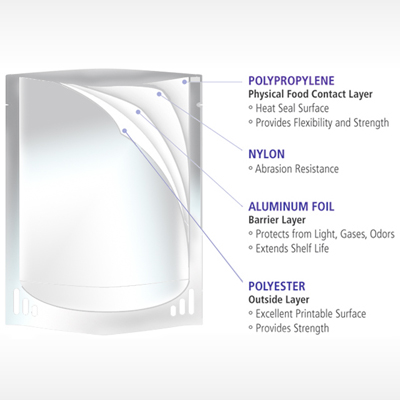

A Retort pouch, unlike metal cans or glass jars, are multilayer laminations allowing for the sterile packaging of a wide variety of food and drink, ranging from water to fully cooked, thermo-stabilized (heat-treated) high-caloric (1,300 on average) food such as Meals, Ready-to-Eat (MREs) which can be eaten cold, warmed by submersing in hot water, or through the use of a flameless ration heater. Retort pouches are used in field rations, space food, camping food, etc. Each layer of the lamination performs different function for the retort pouch. Some of the functions needed in a retort pouch are heat seal ability, thermal stability, gas barrier, rigidity and printability. These functions can be provided in either 3 or 4 layer structures depending on the situation.

A retort pouch is created from a flexible metal-plastic laminate which is able to withstand thermal processing used for sterilisation. The food is first prepared sometimes even raw or semi cooked, and then sealed into the retort pouch. The pouch is then heated to 240-250°F (116-121°C) for several minutes under high pressure, inside retort or autoclave machines. The food inside is cooked, similar to pressure cooking. This process reliably kills all commonly occurring micro-organisms preventing it from spoiling. The packaging process is very similar to canning, except that the package itself is flexible. The lamination structure doesn't allow permeation of gases from outside into the pouch. The particular retort pouches used for several products consist of four layers bonded in a lamination machine. Starting from outside, the layers are:

- Polyester PET Provides a gloss and rigid layer may be printed inside.

- Nylon Bi-Oriented Polyamide provides puncture resistance.

- Aluminum Al provides a very thin but effective gas barrier.

- Polypropylene or CPP which is used as the sealing layer.

The credit of the invention of the retort pouch goes to the United States Army Natick R&D Command, Reynolds Metals Company, and Continental Flexible Packaging, who jointly received the Food Technology Industrial Achievement Award for its invention in 1978. Retortable pouches are extensively used by the U.S. military for field rations (called Meal, Ready-to-Eat, or MREs).

The retort pouch was branded as the next big thing which would take market share of the dominant metal can industry. However, two decades went by and no radical changes were seen. The pouch finally penetrated the US pet food market in May 1999 with Mars Inc.’s launch of “Kal-Kan's Whiskas” cat food in a retort pouch.

After pet food, human food progressively made its way into the pouches. A historical date for the retort pouch though was 15 June 2000 when StarKist, a tuna producer owned by Heinz at the time (now owned by Delmonte) announced, it would launch “StarKist Tuna” in a pouch.

In a statement, the company said that consumers who tested the pouch in home trials conducted by StarKist preferred the new product 5 to 1 over canned tuna. After StarKist other food manufacturers decided to launch their products in retort pouches. These include Chicken of the Sea, Bumble Bee, Tyson Foods, Sara Lee, Mars Inc, etc.

In 2006, Israel’s CLP Industries Ltd. developed a durable stand up retort pouch for Marks & Spencer sauces which can withstand the demands of the retort process and keeps the sauces fresh for 12 months. The pouch's height provides extra eye appeal, as well as plenty of space on the back panel for heating instructions and nutritional labeling.

Besides the retailers, FLEXNEWS discovered that more and more food producers are beginning to market their products in retort pouches. Food giant Unilever, for instance, believes to have benefitted from the pouch. The Anglo-Dutch firm started using retort pouch technology in 2003/2004 with its Dutch soup brand Unox. The launch of Unox soup in a pouch resulted in enormous success. According to some reports Unilever’s products in retort pouches are hope to reach the 100 million units by the end of the year. Now, Tesco PLC, the world's largest retailers, re-designs its private label ready soup from cans to stand up retort pouches in 2013.

Why retort pouches are gaining so much popularity among the producers as well as the customers? To answer this question let us look into few of the advantages of the retort packaging.

The reason food tastes better and is more nutritious in retort pouches lies in the design. Due to their superior surface-to-volume ratio, it takes much less time to cook food in retort pouches than it does in cans. Not only does this design ensure that the food will retain more of its taste and nutritional value, but thanks to the reduced exposure to heat, users often find that their food looks fresher too.

Retort pouches are also an eco-responsible way to package food. The reduced cooking time means that less energy is used in production, and the lighter weight means that transportation costs are reduced as well. The larger package face means that enhanced graphics can be used to increase shelf appeal; the pouches are extremely durable and the packages take up less space in a warehouse and/or on store shelves.

Retort packaging is increasingly proving to be a very effective technique for packaging food products that require extended shelf life, as marketers give great importance to this attribute of the product. Consumer demand for flexible pouches and plastic containers is rising, due to the growing preference for meals ready to eat (MREs) and semi-cooked food products in an increasingly busy and time-constrained society. Thus, while the market for retort pouches is currently only a niche one, it holds immense potential and opportunities for growth.

The introduction of re-closable retort packaging offers an all-in-one serve, seal and store design that can improve the flavour of the product. In a 'heat and eat' society that places a great deal of importance on convenience and the ability to control portions as people want, these retort zipper could open up even more opportunities than those offered only by retort packaging technology.

In the end all we can say is that no one can argue that the consumer is ready for the retort pouch. Maybe back in the 1970s, the consumer did not fully grasp its meaning. But now, with the gradual introduction of the pouch in the pet food industry followed by the food industry, the consumer is aware of its potential.