Packaging and Labeling for Food Safety in B2B Industries

Introduction

In the dynamic and ever-evolving food industry, prioritizing food safety is of utmost importance. A critical facet of this priority lies in the packaging and labeling of food products, particularly within the realm of business-to-business (B2B) transactions. Food safety packaging, packaging tailored to the food industry, B2B food labeling, and strict adherence to the regulations outlined by the U.S. Food and Drug Administration (FDA) all hold pivotal roles in safeguarding consumer health and fostering trust among industry partners. In this extensive guide, we will delve into these integral components, providing an in-depth understanding of their significance and how they seamlessly intertwine to establish a secure and transparent supply chain.

Food Safety Packaging: The Bedrock of Trust

Food safety packaging stands as the initial barrier against contaminants, spoilage, and tampering. Its pivotal role lies in safeguarding the quality and safety of food products as they journey through the supply chain. Here, we highlight essential factors to bear in mind when it comes to food safety packaging in B2B industries:

| Read More: What are the key packaging solutions that cater to B2B food and beverage clients? |

1. Barrier Properties: Packaging materials should act as effective barriers against external factors like oxygen, moisture, and light, which can compromise the quality and safety of food products. For example, vacuum-sealed bags or modified atmosphere packaging (MAP) can help extend the shelf life of perishable goods.

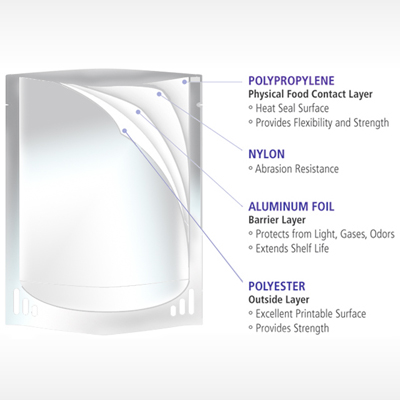

2. Choosing the Right Materials: The selection of packaging materials holds great significance. Frequently, FDA-approved options like food-grade plastics, glass, and metals find common use. Nevertheless, it is crucial to assess the unique requirements of the product and its compatibility with the chosen packaging material.

3. Tamper-Evident Features: Tampering is a significant concern, particularly in B2B transactions where products may change hands multiple times. Tamper-evident seals and features not only deter tampering but also provide a visual indicator if the package has been compromised.

4. Sanitation and Purity: Upholding cleanliness within packaging facilities stands as a paramount measure to avert contamination. Stringent adherence to Good Manufacturing Practices (GMP) guarantees that food packaging remains devoid of harmful microorganisms and foreign matter.

5. Sustainability: In today's environmentally conscious world, sustainable packaging is gaining prominence. B2B companies should explore eco-friendly alternatives that align with their sustainability goals while still meeting food safety standards.

|

Also Read: Labeling Compliance in the Food and Beverage Industry: Navigating Regulations |

Packaging Designed for the Food Industry

Packaging within the food industry isn't one-size-fits-all. Different products have distinct packaging needs. Here are some examples of specialized food packaging:

1. Canning for Long Shelf Life: Canned goods are a classic example of food packaging designed for longevity. The hermetic seal and sterilization process make canned foods safe for extended periods, often without the need for refrigeration.

2. Flexible Packaging: Snack foods, grains, and cereals often come in flexible packaging like pouches and bags. These packages are designed for easy storage and consumption while preserving product freshness.

3. Refrigerated Packaging: Perishable items such as dairy products and meats require packaging that maintains a cold chain. Insulated packaging with cooling elements is often used to prevent spoilage during transit.

4. Aseptic Packaging: Aseptic packaging is used for products like juices and dairy alternatives. It involves sterilizing both the product and the packaging material, ensuring a longer shelf life without the need for refrigeration.

5. Packaging for Beverages: Ranging from bottles to cartons, beverage packaging is crafted to endure the challenges of transportation while safeguarding the integrity of the liquid contents. Additionally, it should incorporate tamper-evident features to ensure safety.

B2B Food Labeling: Transparency and Information

Clear and accurate labeling is not only a regulatory requirement but also a means of providing transparency and building trust in B2B transactions. B2B food labeling should include the following elements:

1. Product Identification: Clearly state the name of the product, including any specific variety or flavor. This helps prevent mix-ups and ensures the right product is used in manufacturing.

2. Ingredient List: An exhaustive ingredient list should be provided, listing all components in descending order of predominance. This information is vital for allergen management and dietary restrictions.

3. Nutrition Facts: Nutritional information, including serving size, calories, and macronutrient content, is crucial for food manufacturers who need to formulate their products accurately.

4. Allergen Information: Highlight allergens in the ingredient list and provide additional warnings if the product was processed in a facility that handles common allergens.

5. Net Weight or Volume: Ensure that the package displays the net weight or volume of the product, which is critical for inventory management and recipe formulation.

6. Date Marking: B2B food products often have a shelf life that needs to be monitored. Include "Use By" or "Best Before" dates to guide proper inventory rotation.

7. Country of Origin: Depending on the product and its source, labeling the country of origin may be a legal requirement.

8. Instructions for Use: If applicable, provide clear instructions for handling, preparation, and storage of the product. This is especially important for ingredients used in food production.

Navigating FDA Regulations: A Must in the Food Industry

Compliance with FDA regulations is an absolute requirement within the food industry. The FDA establishes rigorous guidelines to guarantee the safety and precision of food products, and any lapses in compliance can lead to serious repercussions, including product recalls and legal ramifications. Here's how B2B enterprises can successfully navigate the intricate FDA regulatory landscape:

1. Understand Labeling Requirements: Familiarize yourself with the FDA's labeling regulations, which are detailed in the Code of Federal Regulations (CFR). These regulations cover everything from food identity standards to labeling claims.

2. Nutrition Labeling: Ensure that your product's nutrition facts panel complies with the FDA's requirements. This includes accurate serving sizes, nutrient declarations, and the use of the correct Daily Reference Values (DRVs) and Reference Daily Intakes (RDIs).

3. Allergen Management: Implement robust allergen management protocols to prevent cross-contamination. This includes proper cleaning procedures, segregation of allergenic ingredients, and clear labeling of allergens on finished products.

4. HACCP (Hazard Analysis and Critical Control Points): Implement a HACCP plan to identify and mitigate potential hazards in your food processing operations. This is a critical element of FDA compliance and ensures food safety at every stage.

5. Facility Registration: If your operations encompass the manufacturing, processing, packaging, or storage of food products, it may be imperative to register your facility with the FDA. Neglecting this registration could entail penalties and consequences.

6. Labeling Claims: Be cautious when making health or nutrient content claims on labels. These claims are subject to strict scrutiny, and you must have scientific substantiation to support them.

7. Documentation and Record Keeping: Maintain detailed records of your processes, ingredients, and product testing. These records are essential for traceability and compliance.

Conclusion: Building Trust through Packaging and Labeling

In B2B industries, packaging and labeling are not just logistical concerns; they are fundamental to ensuring food safety and regulatory compliance. The choices made in food safety packaging, the design of packaging for the food industry, and the accuracy of B2B food labeling all have a direct impact on the quality and safety of the final product. Meeting FDA requirements is not merely a matter of legal obligation but a testament to a company's commitment to transparency and consumer well-being.

In a time when consumers are becoming ever more mindful of their dietary choices, the significance of packaging and labeling in nurturing trust cannot be emphasized enough. B2B enterprises that place these elements as a top priority not only guarantee their own prosperity but also bolster the credibility and safety of the broader food supply network. By upholding diligence, transparency, and adherence to standards, B2B industries can consistently deliver secure and dependable food products to consumers, all while cultivating trust with their partners across the supply chain.