Shaft Turret Slitter – JTS-4

Shaft Turret Slitter – JTS-4

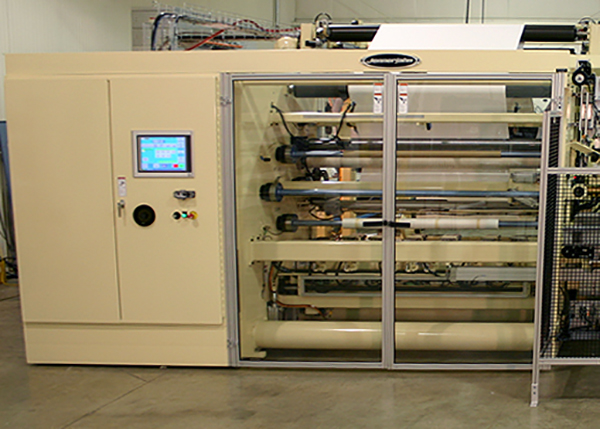

The JTS-4 is a high volume, fully automatic turret winder used to convert a variety of surface sensitive products. The machine is ideal for converters who seek full automation, but who have concerns about web surface scratching or require minimum wound-in tension. By utilizing four shafts instead of just two, the machine’s cycle time is optimized, allowing for very high volume production.

Description

The JTS 4 is a high volume, fully automatic four station turret center winder used to convert a variety of surface sensitive products. This machine optimizes cycle time and provides a higher level of automation than the JTS-2 by utilizing four shafts instead of just two. Station 1 is used for roll starting and winding and station 2 is used for finished roll sealing. Station 3 is used for finished roll removal and station 4 is used for core loading.

As with the JTS-2, a nip roller makes contact with the leading edge of the web momentarily at the beginning of the cycle to assure a quality roll start. The finished roll’s rotation is driven by the center of the rewind shaft to minimize contact with the surface of the roll.

The most common master roll widths for the JTS range from 34 to 73 inches. Typical rewind shafts are 2 or 3 inches in diameter with finished roll diameters up to 10 inches.

Driven unwind stands and load cells can be added for very low-tension applications. Banding systems can also be added to eliminate end-of-roll waste caused by adhesive residue or tearing of the product when the roll is opened by the end user.

Also available as an option, robotic core I.D. and R.F.I.D. labeling systems can be integrated.

Typical Uses: The JTS-4 is a high volume, fully automatic turret winder used to convert a variety of surface sensitive products. The machine is ideal for converters who seek full automation, but who have concerns about web surface scratching or require minimum wound-in tension. By utilizing four shafts instead of just two, the machine’s cycle time is optimized, allowing for very high volume production. Shaft one is used for roll starting and winding, shaft two is used for finished roll sealing, shaft three is used for finished roll removal and shaft four is used for core loading. Like the JTS-2, the machine’s sophisticated tension control system provides superior lane control, allowing for multiple slit production. Typical rewind shafts range in size from 2.0” (50mm) to 3” (76mm) in diameter, with custom diameters available. This machine converts window tint films, coated photo papers, pressure sensitive cast vinyls, coated canvas and much more.

Operator Responsibilities per Cycle: The machine is fully automatic, allowing the operator to assist with roll packaging.

Automation: Cores are staged in a core hopper and transferred to an autoloader station where they are loaded onto rewind shafts. The machine automatically cuts the tails, wraps the tails around the cores, tucks the tails, winds the roll to the desired length, seals the tails of the finished rolls and strips the shaft of finished rolls.