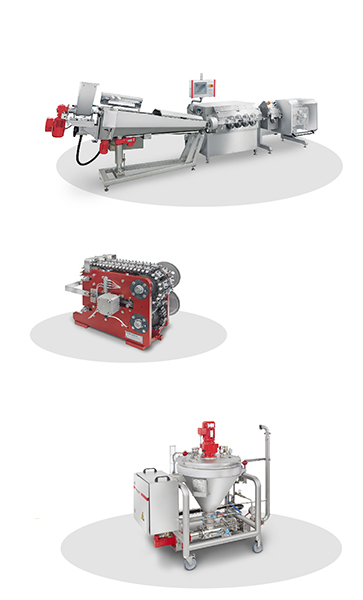

Strada

The universally applicable candy embossing line STRADA® , in the versions 700, 1200, 1500 and 2000, is ideally suited for embossing hard and soft candies, be they filled, unfilled, toffees or chewy candies. In the development of the STRADA® 2000 series in particular, user-friendliness, extended hygienic aspects, high dimensional accuracy of the products produced and the durability of the components were in the foreground.

HKR 2320 conical roller - The universal conical roller is part of the embossing lines STRADA® 700, 1200, 1500 and 2000. The conical roller, made entirely of stainless steel, has four conical rollers for the exact formation of an even cone. The speed of the rollers, the inclination and the temperature of the heating elements can be regulated and can also be saved in the PLC. A looper is also recommended for filled candies.

Leveling machine HZU 2630 - The machine is used in the STRADA® 700, 1200, 1500 and 2000 embossing lines and ensures precise strand calibration with four or five pairs of leveling rollers .

Each pair of rollers can be individually adjusted by an actuator with position control. These values are transferred to the control and assigned to a specific product. This automatically gives the operator the option of adopting the optimal parameters, which minimizes product losses during start-up. Individually heated pairs of rollers with temperature control also ensure uniform conditions during operation.

In the current version, additional emphasis was placed on user-friendliness, enhanced hygiene and occupational safety.

In the event of malfunctions, the mass is very easily removed from the machine, the entire machine is easily accessible with a ground clearance of 200 mm and thus meets today's requirements for cleanliness and occupational safety.

Embossing machine UP 2930 - The embossing machine can be used individually for all sizes. Depending on the desired strand speed, three different types of embossing chain are used for speeds of 50 - 200 strand meters / min.

Due to the balcony construction, the machine has the ability to change embossing chains very quickly - ie within a minute. In the space below, any candy grits can be collected hygienically and sent for further processing.

The current parameters are recorded by means of the RFD chip and are available at any time when the embossing chain is changed.

Burr-free embossing - In combination with the embossing chain , this machine component offers the frequently requested option of producing highly filled candies without burrs. This also applies to special products that are to be visibly packaged in a blister pack.

These embossing chains, manufactured entirely by Hänsel, are specially designed for high speeds. Sophisticated manufacturing technology and material selection reduce wear to a minimum, so that these embossing chains are characterized by a very long service life.

Strand filling pump HSF 2402/2406 - Our strand filling pumps can be used flexibly for all pumpable fillings, from low to high viscosity. Depending on the product properties, poppy or rotary lobe pumps are used. The filling compound is injected into the front part of the sugar cone through a Teflon-coated filling tube. For a technically optimal filling result and a delicious taste experience.