Case Sealers

Case Sealers

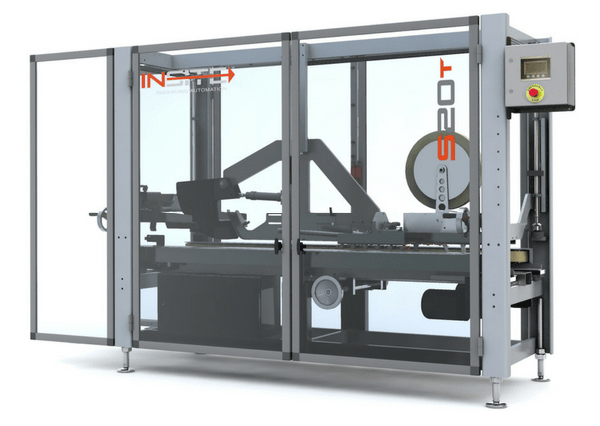

INSITE Packaging Automation’s case sealers boast a clean, minimalist design, despite being packed with numerous functions and features that simply make the case sealing process better for our customers. These features come standard, not as upgrades that you might find with competing sealers. Our case sealer machines handle a large range of case sizes while accommodating enormous variations in the number of cases that can be sealed per minute.

Our case sealers—also referred to as carton sealers and box sealers—are safe, dependable, efficient to operate and effortless to maintain. Let’s explore all the many ways INSITE’s case sealers can improve your business’ packaging operations while saving you money and time.

Key Features of INSITE’s Case Sealers

A sealed case is only part of the story. How you get to a sealed case is just as important. Does your case sealing equipment seal your cases fully and dependably? Does it run reliably without jamming or breaking down? Does it handle the cases firmly enough to control them, but not so firmly that it damages your product? Does it keep your operators safe and run so smoothly and efficiently that it allows those operators to spend time adding value in other parts of your operation? These are questions that an experienced case sealer manufacturer can help you answer. And with INSITE’s thoughtfully designed case sealers, the answer to all those questions is a resounding "yes."A sealed case is only part of the story when it comes to case sealers. How you get to a sealed case is just as important. Ask yourself, does your case sealing equipment:

- Seal your cases fully and dependably?

- Run reliably without jamming or breaking down?

- Handle the cases firmly enough to control them but not so firmly that it damages your product?

- Keep your operators safe?

- Run so smoothly and efficiently that it allows your operators to spend time adding value in other parts of your operation?

These are questions an experienced case sealer machine manufacturer (occasionally referred to as ‘carton sealer machine manufacturers’) can help you answer. With INSITE’s thoughtfully designed top seal packaging machines—the ultimate modern packaging system—the answer to all these questions is a resounding "Yes."

Major flap control

Any good case sealer needs a mechanism to control a case’s major flaps. That’s because any good packing sealing machine manufacturer knows that major flaps are a primary cause of jammed or damaged cases. At INSITE Packaging Automation, we wholeheartedly agree. What we don’t agree with is charging our customers extra money to get something so essential to the case sealing process. Our major flap control feature comes standard with our reasonably priced case sealers, which some of you may refer to as “automatic box sealers” or “automatic box tapers.”

Standard touch-screen controls

Modern packaging equipment should live up to modern usability standards. At INSITE, we believe even base-level case sealers should be “smart” and deliver on high expectations for intuitive system controls. Our case sealers put this control right at the tip of your fingers.

Full-length guard doors

Full-length guard doors with safety switches on our cardboard box sealers provide exceptional operator safety while allowing for full access when the machine is stopped. When your operators run the case sealer machine, guard doors keep them safe. But when they replenish tape or perform preventative maintenance, there’s nothing to get in their way.

Tilt-accessible tape head

Even the tape sealer shows INSITE Packaging Automation’s thoughtful design. Our case sealers’ tape heads tilt easily for superior access or removal. You can replace the existing roll or perform a quick swap of the entire tape head. Either way, this critical piece of case sealing equipment won’t slow down your team.

Spring-loaded side belts

Case sealers need to hold and convey cases without damaging them. INSITE’s case sealing machine uses spring-loaded side belts to get just the right amount of grip. This side belt configuration also allows for a range of case width variances throughout a given production run.

Portability and dexterity

If your operation needs a standalone high-speed case sealer to be in different places at different times, that’s no problem. INSITE’s case sealers have a caster option that allows easy relocation to different lines as plant demand or design changes dictate. If these changes require a different orientation for your automatic carton sealer machine, this poses no problem. Our case sealers easily convert between left- and right-hand operation.