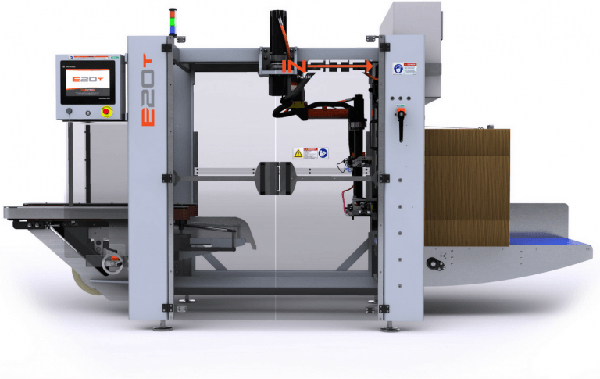

Case Erectors

Case Erectors

Case erectors are simple relative to other packaging equipment. Automatic case erectors convert case blanks into fully erected, bottom-sealed cases. Simple as that.

But if you’ve ever struggled with opening a case, getting a case square or removing a jammed case, you know making a case erector is easy to do but hard to do well. When you step up to an INSITE case erector—also occasionally referred to as a box erector or carton erector—you’ll notice how our work can make your work very easy and very fast.

Key Features of INSITE’s Case Erector

Your case erectors should produce more than just a bottom-sealed case. Cases should be reliably square and come at a reliable speed on a machine that is easy and safe to operate as well as unfailingly automatic. In other words, you should have a case erector you can trust. INSITE Packaging Automation’s box erector machines have been designed from the ground up with features designed to inspire trust.

Automated LxWxD path generation

INSITE’s proprietary, advanced motion control software makes it possible to automatically generate a robot’s path using only the outside dimensions of a case. Replace the mechanical mass found in other erectors with INSITE’s single, simple and reliable SCARA robot.

Opposing-cup case opening

A case erector’s first task is to open a case. Many box erector machines struggle to account for glue over-spray along the manufacturer's joint or the dreaded L-shaped case. In both situations, the opposing-cup effector on INSITE Packaging Automation’s case erector takes care of business.

Robotic pick and pass

Smart use of robotics on INSITE’s auto case erectors enables us to get rid of many of the parts and mechanisms in run-of-the-mill case erectors. We replace these parts and mechanisms with a reliable SCARA robot controlled via the Rockwell brand you know and trust. Goodbye to clunking, clattering, knocking, slamming, fiddling, fixing and finessing. Hello, simple!

Safety and ergonomics

We’ve gone out of our way to ensure your operators' safety and health when using INSITE’s case erecting equipment. The magazine infeed is easy to access and limits loading strain. The open-frame structure puts changeover points and sealing modules within easy reach. Governing bodies agree: INSITE Packaging Automation’s case erectors are ANSI/PMMI B155.1, ISO 13849 Category 3, and UL certified.

Active case squaring

INSITE Packaging Automation’s active case squaring feature means that photo eyes ensure all cases are squared before they are sealed. If a case is skewed, our case erectors’ independently driven side belts respond with a microburst of speed to adjust the case, making it square every time.

Durable & sanitary frame design

INSITE's box erector frames are robust, reliable and hygienic. Made from over-engineered tube- and plate-steel and designed with sanitary standards in mind, these frames are built to withstand a 20+ year packaging equipment asset life.