Polaris

Polaris

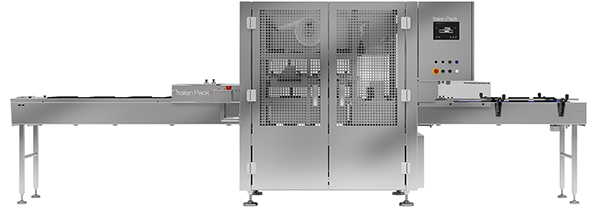

ItalianPack Polaris is our top-of-the-range automated packaging machine designed to meet all the needs of the packaging industry: sealing, partial vacuum, skin, gas flush and modified atmosphere packaging, all available in the protrusion version.

It is highly versatile and customizable, and can accommodate different numbers of dies to satisfy customers’ requirements.

Polaris is available in three different models – Polaris one, double and tre – and can be fitted with one, two or three dies that can be specifically designed to accommodate the same type of tray or different types of trays for maximum speed and high flexibility for high-quality, safe packaging operations.

Our constant research into new technologies and the commitment to developing improved packaging solutions have resulted in a highly versatile machine with cutting-edge technical features for maximum flexibility and reliability.

Another strength is the possibility to custom-design the machine and integrate it with additional technical components to meet complete line requirements.

After three decades of designing and manufacturing sophisticated packaging lines, our technical office is able to offer turnkey, complex packaging solutions fitted with infeed and outfeed conveyors, tray aligners, tray denesters, checkweighers, vibration and dosing units, as well as markers.

ItalianPack Polaris can pack up to 150 trays/min in seal-only mode, 70 trays/min in M.A.P. mode and 60 trays/min in Skin mode.

The same, duly configured die allows for different types of packaging: seal-only, M.A.P. and Skin.

The special film waste rewinder, a PLC touch screen to monitor machine parameters, and dedicated die extraction and change systems are some of the technical features that make this machine stand out among others.

Easy opening

Sealing, vacuum units and feeding chains instantly accessible via front panel for quick and easy maintenance and cleaning operations.

Busch pump

Busch pump

Touch screen control panel

7.2” PLC touch screen, 65,000 display colors, USB port/ Ethernet, 99 packaging programs, language selection, built-in temperature control, menu-driven M.A.P. parameters, skin tray and gradual vacuum.

Optional Die-Change Trolley

Stainless steel trolley for easy, tool-less die-change in less than 2 minutes for maximum safety

Electric Box

AISI 304 stainless steel electric box, wire welded frame, numbered cables, easily accessible for optimized ease of cleaning. Hinged stainless steel panel for easy opening.

Automatic film rewinder

Automatic film rewinder with motordriven film reel shaft and film waste shaft. Inverter-controlled shaft acceleration and deceleration times.

Gas buffer tank

Stainless steel gas buffer tank with pressure regulator.

Teleservice

Remote tele -assistance via the company modem

Marker

Thermal transfer with integrated support.

Denester

Tray denester with up to 6 lines. Quick format change available.

Automated dosing units

Automatic dosing of solids, liquids and granules.

Motorized outfeed conveyor

Motorized outfeed conveyor allows for the channeling of multiple tray lines into a single tray line for weighing, labelling and metal detection