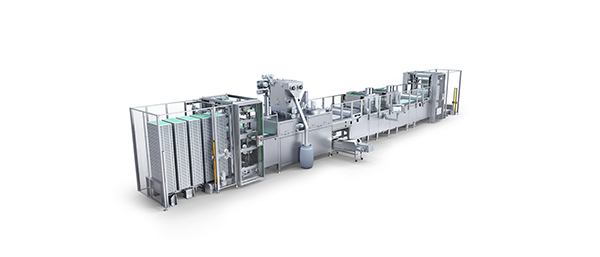

Makat HLM 35 RS

The Highspeed Starch Moulding Plant HLM 35 RS (RS = Roto Step) is controlled by servo-electrical individual drives, so that all courses of movement can be adjusted according to the necessary requirements. At the same time, a high safety-related standard can be guaranteed by the individual torsion survey. No chains for the tray transport are used in the area between feeder and stacker, but the tray transport system MakatRoto-Step, which features by low wear and high precision.

In detail the mogul plant consists of the following sections:

Feeder (continuous elevator chain, tray separation), destarching unit (Servo double turn-over, double drum destarching, subsequent article cleaning, tray filling station, tray side cleaning, servo printing station), servo driven depositor (fixed single stroke system, rotary valve design, 2 hoppers or direct mass feeding, heating system), tray transport system(Roto-Step), stacker (partial stacking unit, continuous elevator chain), Pallet transport, operator panel and switch cabinet.

Benefits:

- All movements can be optimally adjusted to the necessary requirements

- Control of servo-electric single drives

- High standard of safety

- Low wear and high precision