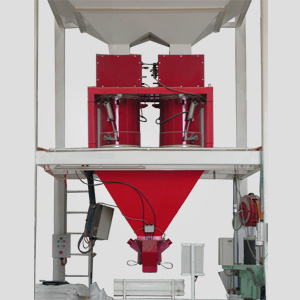

Duplex Net Weigher

An Active Weighing Solutions Net Weigher will fill a variety of open mouth bags to a pre-determined weight with greater speed and accuracy than a Gross Weigher.

Operation

When the operator turns on the Net Weigher; the feed device automatically begins the filling process. When the preset weight is reached, the controller captures the bag weight and, if a bag is in position, it then discharges the weighed bulk product into the bag. The weigher immediately starts refilling while the bag is being discharged from the bag clamp and a new bag positioned.

The Net Weigher is designed to ensure the operators hands are clear of the Bag Clamp, using “whiskers” which must both be energized to activate the Bag Clamp and allow the discharge doors to open. This design also prevents material spillage in the case of a misplaced bag.

Flow Rate

While the bagging rate depends greatly on the material properties of the product being handled and the proficiency of the operator, an Active Weighing Solutions Net Weigher can achieve up to 20 bags per minute.

Accuracy

For free flowing products, an Active Weighing Solutions Net Weigher will typically achieve:

- 25kg bags at up to 10 bags/min at ±20 grams (at 2δ)

- 50kg bags at up to 10-20 bags/min at ± 50 grams (at 2δ)

Non free flowing products may require the bagging rate to be reduced to maintain the required accuracy.

Features

For free flowing product:

- Two position radial feed gate with:

- Independent main & dribble feeds

- Easy feed gate adjustment

- Separate pneumatic & electronic compartments

- Easy access for clean down

- For non free-flowing products

- Single Position Radial Catch Gate with Screw Feeder or Belt Feeder

- EMC 2064 Weigh Batch Processor with

- Automatic in-flight compensation

- Analogue output (configurable)

- Communications to computer or PLC using RS232 or RS422/485

- Full Strain Gauge Load Cell design

- Safety features for safe and reliable weighing:

- Two €œWhiskers€ for operator to strike to initiate bag clamp

- Two Bag Detection switches to ensure bag is correctly placed before feed gate can open.

- “Bird Beak” Bag Clamp with:

Bomb door discharge gate.

24Vdc control voltage throughout the Net Weigher as standard.

Available Outputs

- Data logging and remote diagnostics tool

Construction

Fabricated Mild Steel, Zinc Plated and Powder Coated

Stainless steel contact parts

Fully enclosed design with removable doors for easy access.

Net Weigher Options

- Full 304 or 316 stainless steel construction