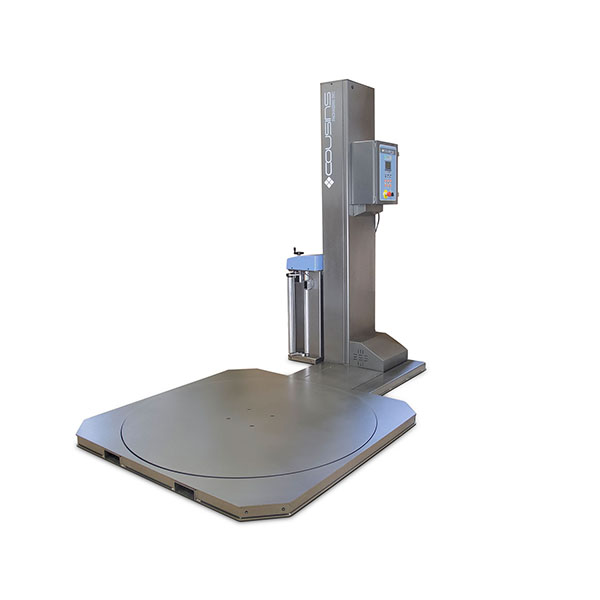

Semi-Automatic Turntable Stretch Wrapper

Semi-Automatic Turntable Stretch Wrapper

The semi-automatic turntable from Cousins Packaging provides a high-quality wrapping solution at an affordable price. Though their appearance may seem basic, their performance is anything but. These durable machines have all the features you need to wrap your pallets and keep up with your production throughput.

Browse through our many turntables semi-automatic machines and contact us today to learn more.

Features of Our Turntable Semi-Auto Machines

With a semi-automatic turntable from Cousins Packaging, the controls are manual, and the wrapping is automatic. This system ensures quality control, secure wrapping, and high productivity. Features of our wrapping machines include:

- High production: Some of our turntables can wrap up to 35 loads an hour, based on settings for load size and the number of wraps.

- Maximum load capacity: Our machines can bear pallets that weigh up to 4,500 pounds, which is much higher than other wrappers in the industry.

- Film threading: Our special film threading device puts the sticky side of the film on the rollers and inside the load for security.

- Electronic controls: From the LCD screen, the operator can power up the machine, set the wrap cycles, change the film carriage, tension and more. With Auto Wrap Cycle Start, it takes only the push of a button to start the wrapping process.

- Sturdy steel construction: Our wrappers are made from steel that has an electro-static powder-coating paint finish. At the base, there are notches at the front and rear for a forklift to lift and move the structure.

See more innovative features included with our best turntable semi-automatic stretch wrappers by reading about our various models below.

Industries That Use Semi-Automatic Wrappers

Many industries have trusted Cousins Packaging to provide cost-effective and efficient wrapping systems for their warehouses and more. Our semi-automatic wrappers will benefit any manufacturer that ships products on pallets. Our solutions have served industries like:

Personal Products — Household Products — Distribution Centers — Beverage — Food — Chemical — And more

No matter your industry, our machines will save you hours of time and costs in labor and materials. See how our semi-automatic turntables will serve your industry needs by contacting Cousins Packaging today from our selection below.

Low Profile 2100-SRT Pallet Wrapper

The Cousins LP-2100 Stretch Wrap Machine has the production speed, load capacity, turntable abilities and control features to ensure pallets are wrapped and contained securely for shipping, storage and transfer. With a wide range of technical features, customizable construction and modification parts, the Cousins Model LP-2100 is suited to fit your every production need.

COUSINS LOW PROFILE 2100-SRT PALLET WRAPPER

The Low Profile 2100-SRT Pallet Wrapper features a variety of benefits, including:

|

|

|

|

|

- 1-35 loads per hour (Single Turntable)

NOTE: Process rates will vary with load size, number of wraps & forklift load/unload time

|

|

|

- Maximum load weight: 4,000 lbs dynamic – 10,000 lbs static

- Maximum load size: 50″ W x 50″ L (71″ max. load diagonal) x 80″ H (plus up to 4″ top overlap)

|

|

|

- 57″ diameter laser-cut steel plate with surround deck protection

- Maintenance-free – 42 roller bearing support system

- Turntable height 2.75″ from floor

- ANSI # 50 direct chain drive c/w chain tensioner

- 3-12 RPM rotational speed c/w soft start acceleration

- 1/2 HP AC variable speed motor

- Final revolution deceleration and positive stop alignment

- Rugged surround deck for added protection, 3-sided loading and pit mounting

- Front and back forklift ports for easy movement

- Accu-Count exact turntable positioning system for additional film savings!

- Optional loading ramp 60″ long x 48″ wide complete with 10″ level porch area available

|

|

|

- 1/2 HP AC variable speed motor

- ANSI #40 direct chain drive c/w shock dampener & Anti-Fall Safety Device

- Maintenance-free carriage guidance system

|

|

|

- NEW Super Rapid Thread II ™ 20″ capacity pre-stretch film carriage

- Special Film Threading Device – Uniquely orientates the sticky side of the film against the pre-stretch rollers and the inside of the load.

- 1/2 HP AC variable speed motor

- Fully electronic dynamic dancer corner compensation

- 33% to 313% fixed stretch capability

- Pre-stretch ratio variable using easy sprocket change

- Carriage Descent Obstruction Safety Shut-Off Device

- Rapid Thread ™ Safety Door with auto power cut-off switch

- Side-mounted film carriage for operator convenience and safety

- Superior film-to-roller contact area

- Lifetime warranty on pre-stretch rollers

|

- Electrical Input Requirements

|

- 115 Volts 1 Phase 60 Hz 15 Amps

|

FEATURES

|

Feature

|

Description

|

|

Control Features

|

- Electronic controls with LCD operator interface

- Power Off – On – Reset switch & Power On indicator light

- Single-button Auto Wrap Cycle Start/Pause

- Cycle Pause for applying top sheets

- Reinforce Wrap control for mid-wrapping

- Base or Top Wraps First program

- Up Only or Up/Down wrap program

- Emergency Stop button

- Turntable Jog button

- Film Carriage Lower & Raise buttons

- Film Tension (Force-to-Load) control

- Separate film carriage raise & lower speed controls

- Operator programmable turntable speed control

- Triple beam automatic load height detection sensor for dark or shiny loads

- Separate 1 to 12 revolution top & bottom wrap control

- Selectable Reduced Film Tension parameters for wrapping top and/or bottom of load

- A – B – C wrap program selector with capability to input and store unique wrapping parameters for each program

|

|

Structural Features

|

- All structural steel construction

- Forklift truck portable base structure design – lifting tubes included for front and rear access

- Structural steel tube machine tower with sheet metal covers

- Electro-static powder-coated paint finish

|