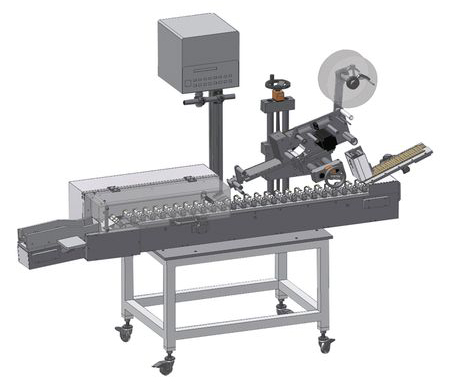

Ampoule labelling machine

This fully automatic labelling system labels not-standing, cylindrical products with different sizes in diameter and length, for example glass tubes, biros or lip sticks. The interchangeable form assemblies, which are only magnetically attached to the conveyor belt, offer clear advantages and significant benefits. As a result, our customers can process dissimilar sized products of different production lines on just one system and within minimum changeover time.

The lying products are fed to the form assemblies via a ledge which includes a separation station. These form assembly are used for products with the diameter of 7-12mm and a length up to a maximum of 100mm. However, the form assemblies can easily be changed so that other products with the diameter of 30mm and up to a length of 120mm can be labelled. Without tools and difficulty this changeover can be done within a short amount of time even if there is a big range of products.

The fully automatic labelling machine is equipped with the label dispensing system RAPID SM. Not only its compact design and its simple and fast operation, but also the output of up to 60m/min is perfect for this labelling system. The unwinder and rewinder for the label carrier strip are integrated. Furthermore, hot stamping unit, thermal transfer printer, laser, inkjet systems and camera systems can be retrofitted. Depending on the product programme these can be either connected or turned off.

Specifications

Length: 2450 mm

Width: 900 mm

Height: 1950 mm

Electronical connection:230 V

Air pressure: 6 bar

Capacity: 30-40 products/minute