LFT 50-60-70 SHRINKWRAPPERS

LFT 50-60-70 SHRINKWRAPPERS

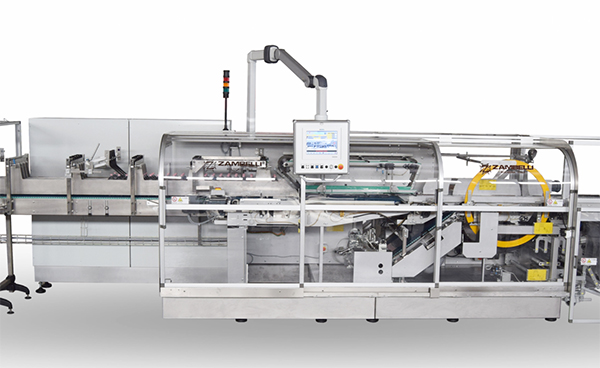

LFT 50-60-70 Shrinkwrappers with lap seal method.

LFT 50-60-70 series shrinkwrappers, automatic machine, suitable for packing containers with LDPE film using the lap seal method, i.e. film is overlapped underneath the product before transfer to the shrink tunnel. Available for film only, flat pad+film or tray+film packing styles. Machine models of this series up to 70 cycles/min capacity. Continuous motion packaging machine suitable to group and package cans, plastic and glass bottles, jars and pots with heat shrink film with or without a cardboard support i.e. a flat pad or a tray. LFT 50-60-70 series shrinkwrappers combine mechanical reliability with state-of-the-art electronics in a flexible and robust machine easy to run and maintain and quick to change over among different product formats.

LFT 50-60-70 series shrinkwrappers sport an unrivaled cantilever frame that allows to separate on the back side all main drives and chains where access is due to maintenance only from the product flow on the front side where operator shall keep full visual control of containers grouping and film wrapping operations. With all parts subject to lubrication isolated on the other side LFT 50-60-70 series shrinkwrappers give the highest guarantee of cleanliness to the operator side where product flows.

All moving parts are protected by safety clutches that trip immediately a torque overload happens in the drive train. In LFT 50-60-70 series shrinkwrappers product grouping is carried out by continuous motion combs pulled by servo-driven chains, system that guarantees optimal product backpressure control and very fast changeover. Film reel unwinding is motor driven at constant speed to pull film to the cutting section without any strain. The single cutting blade is serrated type and its turning movement operated by servomotor allowing the cutting speed to be fine adjusted in the format program according to the bundle size. Advanced cutting technology allows to use very thin films with a dramatic saving. After cutting film is lift to the wrapping section by a vacuum belt timed with the wrapping arm to avoid any film jam even with bundles requiring very long film cuts. Tray+film models are complete with cardboard tray blanks magazine and blank picking by suction cups fitted on an arm with alternate or rotating motion according to the machine model. The cardboard blank is then lifted by pusher dog chains operated by the machine main motor and the tray is formed around the product. Tray sealing by hot melt is carried out by glue guns electronically controlled to eliminate any glue waste.

Shrink tunnel in LFT 50-60-70 series shrink wrappers has been designed to supply adjustable heat to each area of the wrapped film avoiding thermal waste and achieving perfect shrink especially with decorated film. Air flow can be different underneath, aside and above the pack thanks to spreaders and valves adjustable to the pack’s size and the film thickness. LFT 50-60-70 series shrinkwrappers have been conceived to allow fast and reliable format changeover. All parts to be moved are fitted with adjustable handles on metric rods or handwheels with digital readouts so that operator can carry out the format changeover simply following the procedure and adjusting each part to the set position. LFT 50-60-70 series shrinkwrappers are fitted with transparent access doors on all sides allowing fast cleaning and maintenance interventions. Safety switches connected to the emergency circuit immediately stop the machine at access door opening.

LFT 50-60-70 features

- Packaging products in shrink film only, flat pad+shrink film and tray+shrink film

- Control logic by PLC Omron/Siemens/Allen Bradley

- Tray sealing by hot melt unit make Nordson/Melton/Preo/Robatech

- High capacity pad/tray blank magazine

- Stainless steel/washdown executions available

- Complying with UL standards

- Electronic card for remote connection and troubleshooting available

- Data exchange with corporate SCADA available

- Centralized lubrication with automatic pump available

LFT 50-60-70 Technical sheet

- Electric supply: 400VAC–3 Ph+G+N– 50/60hz

- Installed power: from 76 to 96 kW according to machine model

- Compressed air consumption 7,5 Nl/ciclo

- Compressed air pressure: 5 Bar

- Colour Ral 9006 Gray

- Speed up to 70 cases/min