Wrapped around labelling (RML)

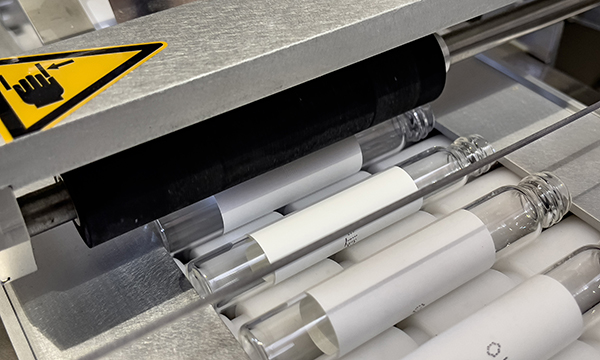

Our RML labeling machine is specifically designed for labeling non-stable cylindrical products, including ampoules, carpules, and syringes. These products are labeled all around, ensuring comprehensive coverage. The labeling station is accessed by the horizontally positioned products through a synchronized roller conveyor belt, which securely affixes the labels onto the product circumference. This system excels in providing exceptional positioning accuracy.

The versatility of our labeling system makes it suitable for various industries such as pharmaceuticals, medical technology, cosmetics, and food. When it comes to labeling products in the cosmetics and food sectors, particularly in the pharmaceutical industry, precise labeling and stringent quality control processes are of utmost importance. Any deviations or errors in labeling could potentially lead to life-threatening situations.

Our labeling machine model offers modular expansion options, ranging from manual loading and unloading to fully automatic assembly and subsequent product collection. For handling narrower products like ampoules or cartridges, format sets (RML-FS) can be utilized.

We take pride in the quality, durability, and user-friendliness of our labeling machines.

Models

RML

- Products: Vials, tubes, ampoules, cartridges, pens, syringe barrels, cartridges, tubes

- Performance: up to 130 cycles/min

RML-T

- Products: Vials, tubes, ampoules, cartridges, pens, syringe barrels, cartridges, tubes

- Performance: up to 80 cycles/min

Basic Equipment

- Base frame with height-adjustable feet

- Conveyor belt with side guide rails

- Stabilization belt

- Product singulation

- Label dispenser

- Thermal transfer printer

- Label pressing unit

- Electronic control

- Touch panel

Additional options

The system can be expanded to include label printing systems such as thermal transfer printing systems, thermal inkjet devices (TIJ), continuous inkjet systems (CIJ) or hot stamping devices. Optional vision systems guarantee quality criteria such as the presence, correctness of print data, label placement on your products and ensure that complaints are settled right from the start.

- TTO pressure module

- camera system(s)

- ejection station

- backup labeller

- magazines

- Packing in blisters

- cartoning unit

- label attendance station

- label ejection station