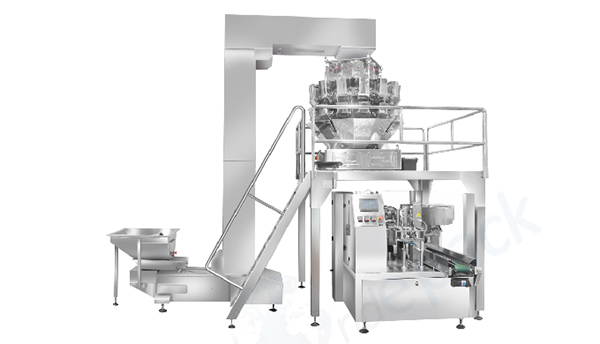

GRANULE ROTARY DOYPACK PACKING MACHINE

Granules such as candy, nut, raisin peanut, chips, melon seeds, chocolate, biscuit, and other grains or irregular auto weighing packing.

Model: WE-D8200-8320

Name: Granule rotary doypack pouch packaging machine

Speed: 16-50 bags/min(Depends on the material)

Bag Size Range: L80-350mm W100-350mm

Filling Volume: 30-5000g

Package Accuracy: ±1g(≦100g) ±1% (>100g)

Voltage: 220V/380V

Power:2.3-7.5KW;

Air compressor: 0.6-1.2 m³/min

Gross Weight:1800KG

Gross Demention: L4500*W2820*H3700mm(WE-D8200)

1. Multi-heads weigher: Set a ‘typical target’ weight per pack. The product is fed to the top of the multi-head weigher where it is dispersed to the pool hoppers. Each pool hopper drops the product into a weigh hopper beneath it as soon as the weigh hopper becomes empty. The weigher’s computer determines the weight of the product in each individual weigh hopper and identifies which one contains the weight closest to the target. The multi-head weigher opens the hopper and the product falls into the opening premade bags via the funnel. An extra layer of hoppers (‘booster hoppers’) can be added to store product that has been weighed in the weigh hoppers but not used in a weighment, thus increasing the number of suitable combinations available to the computer and so increasing speed and accuracy.

2. Rotary packaging machine work 8 steps in turn.

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise.

2. Eight stations rotary design, compact and reasonable arranged in the smallest amount of space, to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials.

3. The main configuration is the Siemens PLC control system, the touch screen can set a variety of languages, simple operation, and easy maintenance.

4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance.

5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing.

6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement.

7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

1. we provide videos and an instruction manual to show the process of installation.

2. we provide training for installation for free in our factory.

3. we can send a technician to the buyer’s factory to install the machine and provide a training course.

1. One-year warranty and free lifetime technique support.

2. Free spare parts would be supplied if the machine broke within the warranty period.

3. After the warranty period, the spare parts for replacement are offered based on a certain charge.